Why Non-Destructive Testing (NDT) Is Essential for Industrial Asset Integrity

- Stephen Fike

- Dec 11, 2025

- 3 min read

Industrial facilities rely on the continuous performance of critical assets—pressure vessels, pipelines, storage tanks, electrical systems, welds, structural components, and rotating equipment. When these assets fail unexpectedly, the outcome can be severe: costly downtime, environmental releases, equipment loss, and major safety risks.

This is why Non-Destructive Testing (NDT) plays a central role in maintaining asset integrity, optimizing reliability, and supporting regulatory compliance.

At Assured NDT, we help industrial facilities across the U.S. detect hidden defects early through advanced testing methods that provide accurate, actionable insights—without damaging the equipment being evaluated. Below, we break down why NDT is essential for industrial asset integrity and how it strengthens maintenance programs.

What Is Non-Destructive Testing (NDT)?

Non-Destructive Testing refers to a group of inspection technologies used to evaluate the condition of assets without dismantling, destroying, or disrupting equipment.

Common industrial non-destructive testing methods include:

Ultrasonic Testing (UT)

Magnetic Particle Testing (MT)

Liquid Penetrant Testing (PT)

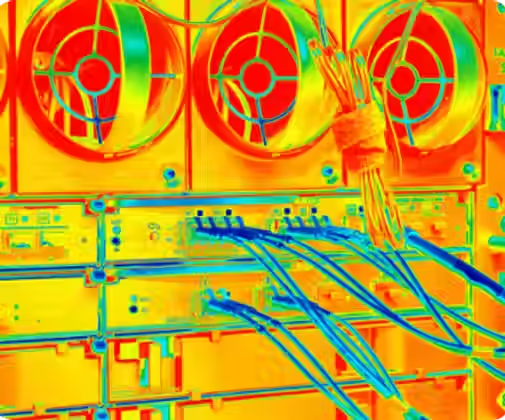

Infrared Thermography (IR)

Radiography (RT)

Visual Weld Inspection (VT)

Vibration & Condition Monitoring

Dissolved Gas Analysis (DGA) for transformers

Each provides unique insights into material condition, internal defects, and structural integrity—making NDT a cornerstone of modern reliability programs.

Why Non-Destructive Testing Is Essential for Asset Integrity in Industrial Facilities

1. Detects Hidden Damage Before Failure Occurs

Industrial assets degrade from:

Heat cycles

Vibration

Mechanical stress

Corrosion

Fatigue

Overloading

Many defects form internally long before they show surface symptoms.

NDT identifies issues early, allowing maintenance teams to intervene before failures cause production losses or safety incidents.

2. Supports Predictive & Condition-Based Maintenance

Industrial operations are moving away from time-based maintenance and adopting predictive maintenance.

NDT is the foundation of this shift because it provides:

Measurable data

Repeatable inspections

Trend analysis

Degradation tracking

This helps reliability managers forecast failures and plan repairs during scheduled downtime.

3. Ensures Compliance With Industry Standards

Industrial sectors must comply with:

OSHA 1910

NFPA 70B (annual IR thermography)

API 510 / 570 / 653

ASME & ASTM codes

IEEE transformer testing guidelines

Insurance requirements

NDT is often required by law or by internal safety policies. Assured NDT provides inspection reports aligned with these standards to simplify compliance and documentation.

4. Protects Worker Safety

Asset failures can lead to:

High-pressure equipment rupture

Arc flash events

Structural collapse

Chemical releases

Fire or explosions

By detecting cracks, corrosion, overheating, or insulation breakdown early, NDT reduces risk for on-site personnel.

5. Extends Equipment Lifespan

Proper NDT helps facilities:

Prevent premature equipment replacement

Evaluate weld quality

Monitor wall thickness loss

Maintain structural integrity

Reduce stress on aging assets

Extending asset lifespan directly reduces capital expenditure.

6. Minimizes Downtime and Production Loss

Unplanned downtime is one of the highest-cost risks in manufacturing and heavy industry.

NDT prevents operational interruptions by:

Identifying issues early

Allowing timely repair planning

Avoiding catastrophic failures

Supporting shutdown optimization

Facilities using NDT report up to an 80% reduction in unplanned outages.

7. Offers a Non-Intrusive, Non-Destructive Testing Approach

Unlike destructive testing—where a component must be removed or damaged—NDT preserves equipment integrity during inspection.

That means:

No shutdown required for most tests

No equipment loss

No disruption to operations

Industrial uptime remains intact while gathering high-quality diagnostic data.

Industrial NDT Services from Assured NDT

Assured NDT provides comprehensive non-destructive testing for:

Manufacturing plants

Power generation facilities

Chemical plants

Refineries

Food & beverage processing

Utilities

Commercial facilities

Pulp & paper mills

Marine & transportation sectors

Our certified inspectors deliver:

Accurate diagnostics

Clear recommendations

Compliance-ready documentation

Safe, efficient on-site inspections

Nation-wide service coverage

If asset integrity is a priority in your facility, NDT should be a core component of your maintenance program.

Strengthen Your Asset Integrity Strategy Today

Assured NDT helps industrial facilities reduce risk, improve reliability, and extend asset life with advanced NDT services.

📞 Schedule an inspection or request a quote at assuredndt.com/contact

FAQs: Why Non-Destructive Testing (NDT) Is Essential for Asset Integrity

1. What role does NDT play in asset integrity?

NDT provides accurate data on equipment condition, allowing facilities to detect damage early, reduce failures, and maintain safe, reliable operations.

2. Which NDT methods are used in industrial facilities?

Common methods include ultrasound, magnetic particle, dye penetrant, infrared thermography, radiography, and visual inspection.

3. How does NDT reduce maintenance costs?

NDT identifies defects before failure, enabling planned repairs instead of expensive emergency work or full equipment replacements.

4. Is NDT required for compliance?

Yes. Standards like NFPA, OSHA, API, ASME, and insurance carriers often require periodic non-destructive testing to verify asset integrity.

5. How often should industrial equipment undergo NDT?

Frequency depends on asset type, environment, and operational load. Many facilities perform NDT annually or during scheduled shutdowns.