Changing the Maintenance Culture: From Reactive Repairs to Predictive Maintenance in Manufacturing

- Stephen Fike

- Nov 7, 2025

- 4 min read

The Maintenance Mindset Shift: From “Fix It When It Breaks” to “Prevent It Before It Fails”

For decades, many facilities operated under a reactive maintenance model — waiting for equipment to fail before acting. While this approach might seem cost-effective in the short term, it leads to unplanned downtime, higher repair costs, safety risks, and production loss.

Today, leading organizations are changing that narrative. With advances in predictive technologies such as infrared thermography, vibration analysis, and oil diagnostics, maintenance teams can detect early signs of failure — often weeks or months before a breakdown occurs.

At Assured NDT, we help companies evolve from reactive repairs to predictive reliability through condition-based electrical maintenance programs that align with NFPA 70B (2023) and OSHA safety standards.

The Cost of Reactive Maintenance

Reactive maintenance is sometimes called “run-to-failure.” The problem? Failures don’t just damage equipment — they disrupt entire operations.

Common consequences of reactive maintenance include:

Unplanned downtime: Each hour of lost production can cost thousands — or even hundreds of thousands — of dollars.

Safety hazards: Sudden failures can cause arc flash events, fires, or other worker safety risks.

Increased costs: Emergency repairs and expedited parts replacement are always more expensive.

Shortened asset lifespan: Constant stress and overheating degrade components prematurely.

Regulatory and insurance exposure: Lack of preventive documentation can impact compliance and claims.

Reactive maintenance turns minor issues into major crises — and keeps teams trapped in a cycle of firefighting rather than problem-solving.

The Predictive Maintenance Advantage

Predictive maintenance (PdM) leverages real-time data and diagnostic technologies to monitor asset health and forecast when maintenance should be performed.

Unlike reactive or even time-based preventive maintenance, predictive maintenance allows for data-driven decision-making — meaning maintenance happens only when and where it’s truly needed.

Key benefits include:

✅ Reduced downtime: Identify faults before they trigger a failure.

✅ Extended asset life: Manage load, temperature, and wear proactively.

✅ Improved safety: Prevent electrical hazards before they become incidents.

✅ Lower maintenance costs: Plan repairs around production schedules.

✅ Compliance readiness: Maintain NFPA 70B and OSHA documentation.

At its core, predictive maintenance replaces “reaction” with precision — and transforms maintenance from a cost center into a profit-preserving system.

Tools That Power Predictive Maintenance in Manufacturing

A successful predictive maintenance program integrates multiple technologies and data streams.

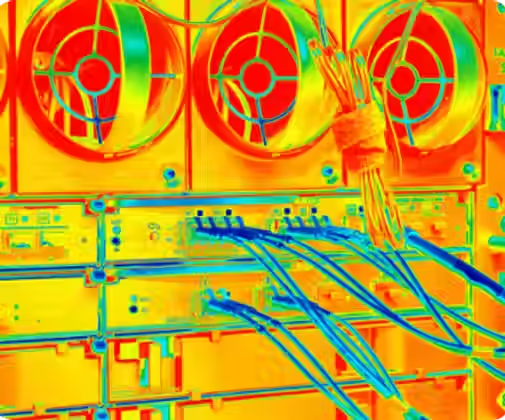

Infrared Thermography

Detects overheating components, loose connections, and insulation breakdowns before failure. Now required annually under NFPA 70B (2023) for energized electrical systems.

Vibration Analysis

Monitors motor and rotating equipment to identify imbalance, bearing wear, or alignment issues.

Oil and Dissolved Gas Analysis (DGA)

Analyzes transformer and mechanical system lubricants to detect contamination or electrical discharge.

Ultrasonic Testing

Identifies air or gas leaks, partial discharge, and mechanical friction points.

Electrical Testing

Includes breaker timing, insulation resistance, and circuit analysis — ensuring protective devices function as intended.

Assured NDT combines these tools into comprehensive, condition-based maintenance programs that improve reliability across the facility.

How to Build a Predictive Maintenance Culture in Manufacturing

Technology alone doesn’t create reliability — culture does. Shifting from reactive to predictive maintenance requires new habits, workflows, and leadership priorities.

Here’s how successful organizations make the transition:

1. Leadership Commitment

Executives and facility managers must view predictive maintenance as a strategic investment, not a budget line item.

2. Train and Certify Teams

Empower technicians with training in infrared thermography, vibration analysis, and NFPA 70B compliance.

3. Start with Critical Assets

Focus first on equipment with the highest cost of failure — transformers, switchgear, and production line motors.

4. Document and Trend Everything

Track anomalies over time to validate improvements and justify ROI.

5. Communicate Wins

Share maintenance successes across departments to reinforce the program’s value.

At Assured NDT, we help facilities build predictive programs that integrate seamlessly into existing operations — improving reliability, compliance, and culture simultaneously.

Predictive Maintenance and NFPA 70B: Working Together

The NFPA 70B (2023) standard redefines electrical maintenance as a condition-based process. That means predictive tools like thermography are not optional — they’re required for compliance.

Assured NDT’s predictive maintenance services align directly with NFPA 70B’s intent:

Annual thermography inspections of energized systems

Condition-based testing for electrical safety

Qualified personnel conducting and documenting results

Comprehensive trending reports for audit readiness

By following NFPA 70B, you not only ensure compliance — you build the foundation of a predictive culture.

Assured NDT: Your Partner in Predictive Reliability

Assured NDT is trusted by manufacturers, data centers, and commercial facilities nationwide for our technical expertise in predictive electrical maintenance.

Our ASTM certified specialists provide: ✅ Infrared thermography and condition-based testing ✅ Electrical system reliability audits ✅ NFPA 70B-compliant maintenance programs ✅ Reporting and documentation for compliance and insurance audits

We don’t just find problems — we help you prevent them.

The Bottom Line: Predictive Maintenance Isn’t the Future — It’s the Standard

As NFPA 70B and modern reliability programs evolve, predictive maintenance is no longer a competitive advantage — it’s a compliance requirement and operational necessity.

By moving away from “fix it when it breaks,” your facility can achieve:

Safer workplaces

Lower costs

Longer equipment lifespan

Greater uptime and profitability

Contact Assured NDT today to learn how predictive maintenance can help transform your facility’s reliability and compliance program.

Frequently Asked Questions About Predictive Maintenance

1. What’s the difference between preventive and predictive maintenance?

Preventive maintenance follows a time-based schedule, while predictive maintenance uses real-time data to determine when maintenance is actually needed — saving time and cost.

2. How does predictive maintenance reduce downtime?

By identifying early signs of failure, predictive tools allow maintenance teams to repair assets during planned outages instead of reacting to unexpected breakdowns.

3. What technologies are used in predictive maintenance?

Infrared thermography, vibration analysis, oil testing, ultrasonic analysis, and circuit testing are among the most effective predictive maintenance technologies.

4. How does predictive maintenance relate to NFPA 70B?

NFPA 70B (2023) mandates condition-based electrical maintenance — making predictive testing like thermography a requirement for compliance.

5. How can Assured NDT help implement predictive maintenance?

Assured NDT designs and delivers NFPA 70B-compliant predictive maintenance programs that combine certified diagnostics, trending, and documentation to reduce risk and improve reliability.

Contact Assured NDT today to learn how predictive maintenance can help transform your facility’s reliability and compliance program