Benefits of Non-Destructive Testing for Industrial Equipment

- Stephen Fike

- Dec 4, 2025

- 3 min read

Industrial facilities rely on complex mechanical, electrical, and structural systems to operate safely and efficiently. But as equipment ages and production demands increase, undetected failures can lead to costly downtime, safety risks, or even catastrophic asset damage. This is why more facilities are turning to Non-Destructive Testing (NDT) — a proven method for evaluating equipment health without shutting down systems or causing disruption.

At Assured NDT, we help manufacturers, utilities, commercial buildings, and industrial plants protect their assets with certified NDT inspections designed to detect hidden defects early. From weld integrity to electrical anomalies, NDT provides the insight you need to prevent failures before they happen.

Below are the top benefits of non-destructive testing for industrial equipment — and why it should be a core part of every maintenance strategy:

Extends Equipment Lifespan

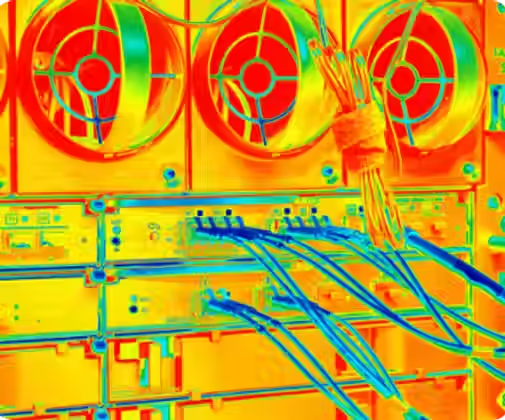

Industrial assets degrade over time due to temperature cycles, vibration, corrosion, wear, and stress. NDT techniques such as ultrasound, thermography, and magnetic particle inspection help identify early-stage defects long before they become serious.

This allows facilities to:

Repair equipment before damage spreads

Avoid premature replacements

Prolong asset life and reduce capital expenditures

Early detection = lower total cost of ownership.

Minimizes Unplanned Downtime

Downtime is one of the most expensive problems industrial facilities face. NDT is one of the few maintenance tools capable of detecting internal deterioration while equipment remains in service.

Benefits include:

Finding faults before they force emergency shutdowns

Scheduling repairs during planned outages

Preventing failures that could disrupt production

With NDT, maintenance becomes proactive—not reactive.

Enhances Worker and Facility Safety

Many industrial failures result in safety incidents: arc flash events, ruptured pressure vessels, structural collapse, electrical fires, and more.

NDT helps identify unsafe conditions by detecting:

Cracks or fractures in load-bearing components

Insulation breakdown in electrical systems

Overheating connections

Corroded pipelines or pressure systems

By discovering risks early, facilities protect workers and reduce liability.

Supports Compliance With Industry Standards

Industrial facilities must comply with various safety and inspection requirements, including:

API, ASME, ASTM, and IEEE standards

Insurance carrier guidelines

NDT provides documentation needed for audits, licensing, compliance, and insurance renewals. Many industries — including energy, manufacturing, aviation, and food processing — rely on NDT as a required method of asset evaluation.

Reduces Maintenance Costs

Because NDT pinpoints the exact location and severity of defects, it eliminates unnecessary service work.

This allows teams to:

Target repairs precisely

Avoid “blanket replacements”

Optimize labor spending

Reduce spare-parts waste

The result is a more efficient, cost-effective maintenance program.

Allows Inspections Without Equipment Damage

As the name suggests, Non-Destructive Testing does not harm the equipment being inspected. Unlike destructive testing — where a component is sacrificed to determine strength — NDT preserves assets while still delivering accurate data.

This makes NDT ideal for:

Live electrical systems

Welds and pressure vessels

Rotating machinery

Structural steel

Piping and storage tanks

Transformers and switchgear

You get valuable insight without taking equipment offline.

Provides Data for Predictive Maintenance Programs

Modern industrial facilities are shifting from reactive to predictive maintenance. NDT supports this strategy with measurable, repeatable data.

Using NDT trend analysis, facilities can:

Track deterioration over time

Identify patterns in equipment behavior

Plan long-term asset management

NDT lays the foundation for a smarter, more data-driven maintenance culture.

Why Choose Assured NDT for Industrial Testing?

Assured NDT provides nationwide NDT services performed by certified Level II and Level III inspectors. Our team combines technical expertise with advanced diagnostic tools to help industrial facilities improve reliability and reduce operational risk.

We offer:

Ultrasonic testing

Magnetic particle inspection

Liquid penetrant testing

Visual weld inspection

Arc flash studies and electrical system analysis

Whether you manage a manufacturing facility, commercial building, utility plant, or multi-site operation — Assured NDT delivers the insight you need to maintain safe, dependable operations.

Ready to Protect Your Facility’s Most Critical Equipment?

Contact Assured NDT today to schedule NDT services anywhere in the United States.

📞 Request a quote or consultation at assuredndt.com/contact

FAQs: Benefits of Non-Destructive Testing for Industrial Equipment

1. What is non-destructive testing (NDT)?

NDT is a collection of inspection methods used to evaluate the condition of equipment without damaging or removing it from service.

2. What industries benefit most from NDT?

Manufacturing, energy, utilities, chemicals, aerospace, commercial buildings, data centers, and oil & gas facilities regularly use NDT to detect early-stage defects.

3. How does NDT help prevent equipment failure?

By identifying cracks, corrosion, overheating, insulation defects, and material fatigue before the equipment fails.

4. Is NDT required for regulatory compliance?

Yes. Many standards — including OSHA, NFPA, API, ASME, and insurance carriers — recommend or require NDT as part of preventive maintenance.

5. How often should industrial facilities perform NDT?

Frequency depends on equipment type, load, age, and environmental conditions. Many assets require annual or semi-annual inspections.