Why Infrared and NDT Should Be Part of Every 2026 Maintenance Plan

- Stephen Fike

- Nov 21, 2025

- 4 min read

Planning for 2026: A Smarter Approach to Maintenance

As we approach 2026, facility and reliability managers across industries are already mapping out next year’s maintenance budgets and priorities. But here’s the truth: many still overlook one of the most cost-effective and compliance-driven tools available — infrared thermography and non-destructive testing (NDT).

With the NFPA 70B (2023) standard now enforcing annual condition-based electrical inspections, infrared and NDT technologies are no longer “nice to have” — they’re a core requirement for safe, efficient operations.

At Assured NDT, we help organizations across the U.S. integrate infrared thermography and non-destructive testing into their maintenance planning — creating safer, more reliable facilities and reducing unplanned downtime by up to 80%.

The Shift from Reactive to Predictive

Traditional maintenance programs relied on a “run-to-failure” approach — fix it when it breaks. But this strategy is no longer sustainable in today’s high-demand environments.

Predictive maintenance powered by infrared thermography and NDT allows you to:

Detect issues early (before breakdowns or fires occur)

Schedule repairs during planned downtime

Comply with NFPA 70B, OSHA 1910, and insurance requirements

Extend the lifespan of critical electrical and mechanical assets

In short, these inspections transform maintenance from a cost center into a strategic performance advantage.

Why Infrared Thermography Belongs in Every 2026 Plan

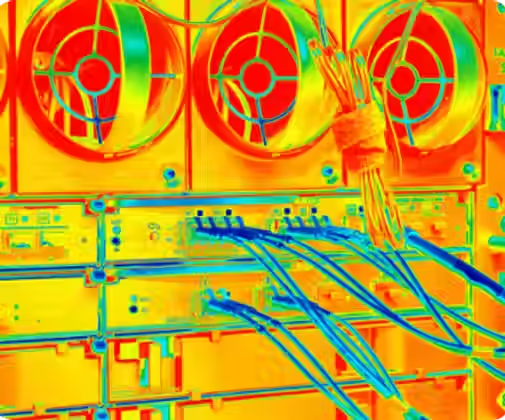

Infrared thermography uses specialized thermal imaging to detect heat anomalies in electrical and mechanical systems. These temperature variations can indicate:

Loose or corroded electrical connections

Overloaded circuits or transformers

Bearing or motor failures

HVAC system inefficiencies

Moisture intrusion in building envelopes

Benefits for Your 2026 Maintenance Strategy:

Prevent costly downtime: Identify issues months before they cause outages.

Meet compliance standards: Stay aligned with NFPA 70B and insurance mandates.

Save energy: Detect inefficiencies and reduce power waste.

Prioritize repairs: Focus budget where risk is highest.

The Role of Non-Destructive Testing (NDT) in Preventive Maintenance

NDT complements infrared thermography by providing in-depth insights into material and structural integrity — without damaging components.

Common NDT techniques include:

Ultrasonic testing (UT) – detects internal flaws in welds and metals.

Eddy current testing (ET) – identifies surface and subsurface cracks.

Magnetic particle (MT) and liquid penetrant testing (PT) – reveal surface defects.

Infrared thermography (IR) – detects overheating or hidden mechanical stress.

Adding NDT to Your 2026 Plan Helps You:

✅ Avoid catastrophic failures in pressure vessels, pipelines, and load-bearing components. ✅ Comply with ASME, API, and ASTM standards. ✅ Optimize capital planning with accurate asset health data. ✅ Build confidence with insurers and auditors.

NFPA 70B: The 2026 Compliance Imperative

The NFPA 70B 2023 update formally changed maintenance recommendations into enforceable standards. By 2026, every U.S. facility will be expected to:

Perform annual infrared thermography on energized electrical systems.

Document findings in a Condition-Based Maintenance (CBM) program.

Maintain inspection reports for audit and insurance review.

Failing to meet these requirements could expose your organization to: ⚠️ OSHA citations and fines ⚠️ Voided insurance claims ⚠️ Increased downtime and safety risk

Including Assured NDT’s inspection services in your 2026 maintenance budget ensures full NFPA 70B compliance — and peace of mind.

Building a Future-Proof Maintenance Program

To stay ahead in 2026 and beyond, forward-thinking organizations should:

1️⃣ Budget now for annual infrared and NDT inspections. 2️⃣ Integrate thermography reports into digital maintenance management systems (CMMS). 3️⃣ Partner with certified experts who deliver actionable data, not just images. 4️⃣ Train internal teams to interpret reports and trend data over time.

Assured NDT partners with engineering, facility, and risk management teams nationwide to deliver turnkey inspection programs tailored to your needs and compliance goals.

Start Planning Your 2026 Infrared & NDT Program Today

Don’t wait until the new year to plan smarter maintenance. Get ahead of compliance — and protect your facility, assets, and people.

Contact Assured NDT to schedule a consultation and start building your 2026 Infrared and NDT Maintenance Strategy today.

Frequently Asked Questions: Infrared & NDT in 2026 Maintenance Plans

1) Why should infrared and NDT be included in 2026 maintenance plans? Infrared and NDT inspections detect electrical and mechanical issues before they cause failures, helping facilities prevent downtime, improve safety, and meet NFPA 70B compliance requirements.

2) What are the main differences between infrared and NDT testing?

Infrared thermography identifies heat anomalies in live systems, while NDT (ultrasonic, magnetic, or eddy current testing) analyzes material and structural integrity without causing damage.

3) Is infrared thermography required under NFPA 70B? Yes. The 2023 update mandates annual infrared inspections for energized electrical systems as part of a documented Condition-Based Maintenance (CBM) program.

4) How often should NDT be performed? NDT frequency depends on system type and usage. Most facilities perform NDT annually or biannually as part of preventive maintenance programs.

5) How does infrared thermography save money? By detecting faults early, infrared inspections reduce costly emergency repairs, prevent downtime, and improve energy efficiency — often delivering 5–10x ROI.

6) Can infrared and NDT be performed during normal operations?

Yes — both testing methods are non-invasive and can be completed while systems remain energized or online, minimizing disruption.

7) Does Assured NDT offer nationwide service? Yes. Assured NDT provides infrared and NDT inspections across the U.S., with teams strategically located to support facilities nationwide.

8) How do I start building my 2026 maintenance plan? Contact Assured NDT for a consultation. We’ll help you create a customized infrared and NDT inspection schedule aligned with your compliance, safety, and operational goals.